DRYERS IN BIN

GSI has built a full line of in bin drying products on our historical knowledge of air flow and heating. In bin dryers offer the highest grain quality with various management techniques. In-bin dryers can be the right option for you if you have smaller storage bins spread across multiple sites, or a specialty application like rice.

PRODUCT LINEUP

TOPDRY BATCH & AUTOFLOW DRYERS

TOPDRY

Though the TopDry is technically drying grain in the bin, it is really more like an out of bin dryer. Combine the TopDry’s limited depth, roof drying floor and high capacities with the same high capacity fans used on our Portable Dryers and you get capacities equal to our largest Stack Portable Dryer.

The TopDry is available in a completely manual batch version and an automatic AutoFlow version which operates exactly the same as our out of bin dryers, requiring the same support items such as a wet tank.

The TopDry is available in a completely manual batch version and an automatic AutoFlow version which operates exactly the same as our out of bin dryers, requiring the same support items such as a wet tank.

KEY FEATURES

• Capacities/HR:

Up to 2,176 BPH Dry & Cool @ 5 pt. removal

• Operation Type: Dry/Cool

• Fuel: LP or Natural Gas

• Operation Type: Dry/Cool

• Fuel: LP or Natural Gas

• Electrical:

1 and 3 phase

• Native cooling heat and aeration air Recovery

GSI DESIGN III STIRATOR

STIRATOR

For over 30 years, the Design III StirAtor has been the most dependable stirator system. Though among the lowest in capacity, the Design III can turn a grain bin into a drying system at a minimum investment. A high temperature, above 10 degree rise, bin dryer has to have a way to dry all the grain to the same moisture. Just running a fan & heater on a bin full of grain will result in 5% grain at the bottom with no moisture removed on the top. GSI’s StirAtor ensures that all the grain is the same moisture, with no wet tank required; all you need is a fan & heater and an auger to fill the bin.

KEY FEATURES

• Typical Capacities/HR:

Up to 300 BPH Dry & Cool @ 5 pt. removal at 120 to 140 deg/F. operating temperatures

• Operation Type: Dry/Cool

• Fuel: LP or Natural Gas

• Operation Type: Dry/Cool

• Fuel: LP or Natural Gas

• Electrical:

1 and 3 phase

GSI MODEL 84 GRAIN FLOW BIN DRYERS

GRAIN FLOW

The addition of a GSI Model 84 Grain Flow to a conventional drying bin provides a significant increase in capacity over a standard bin drying system. It removes only the dried grain at the floor. The Calc-U-Dri controls provide complete operational and moisture control. With Grain Flow, there’s no need for a wet bin, but one can be used for maximum capacity. With shallow depths the system achieves higher airflows and capacity. Pulling only the dried grain off the bottom of the bin improves efficiency while preserving exceptional grain quality.

A loading device and equipment to take away the dried grain is the only other required equipment. The GSI Trans-Fer pneumatic system is a perfect match to the Grain Flow system

A loading device and equipment to take away the dried grain is the only other required equipment. The GSI Trans-Fer pneumatic system is a perfect match to the Grain Flow system

KEY FEATURES

• TYPICAL CAPACITIES/HR:

Up to 600 BPH Dry & Cool @ 5 pt. removal at 160 degree F. operating temperatures

• Operation Type: Dry/Cool

• Fuel: LP or Natural Gas

• Operation Type: Dry/Cool

• Fuel: LP or Natural Gas

• Electrical:

1 and 3 phase

GSI LOW TEMPERATURE BIN DRYING

LOW TEMPERATURE BIN DRYING

GSI’s Low Temp Bin Dryers are not so much a product, but more a combination of GSI’s quality products and specific grain management techniques into a drying system. Using any GSI grain bin, preferably a stiffened model combined with GSI’s 1750 rpm Centrifugal Fan(s) and upstream low temp burners, you have the necessary components to dry in bin without the need for a Stir-Ator or other equipment. Moisture control is provided using a simple humidistat with your own management of temperature and humidity. By controlling airflow when humidity and temperature are in equilibrium with the desired moisture, all of the grain is brought to the desired moisture without over drying.

KEY FEATURES

• TYPICAL CAPACITIES/HR:

1 bin fill per harvest season up to 31,900 bu./year using a 48’ 6 ring 4.00” bin

• Operation Type: Near Ambient High Airflow Drying

• Fans: 1750 Centrifugal

• Operation Type: Near Ambient High Airflow Drying

• Fans: 1750 Centrifugal

• Burners:

Upstream

• Fuel: LP or Natural Gas

• Electrical:

1 and 3 phase

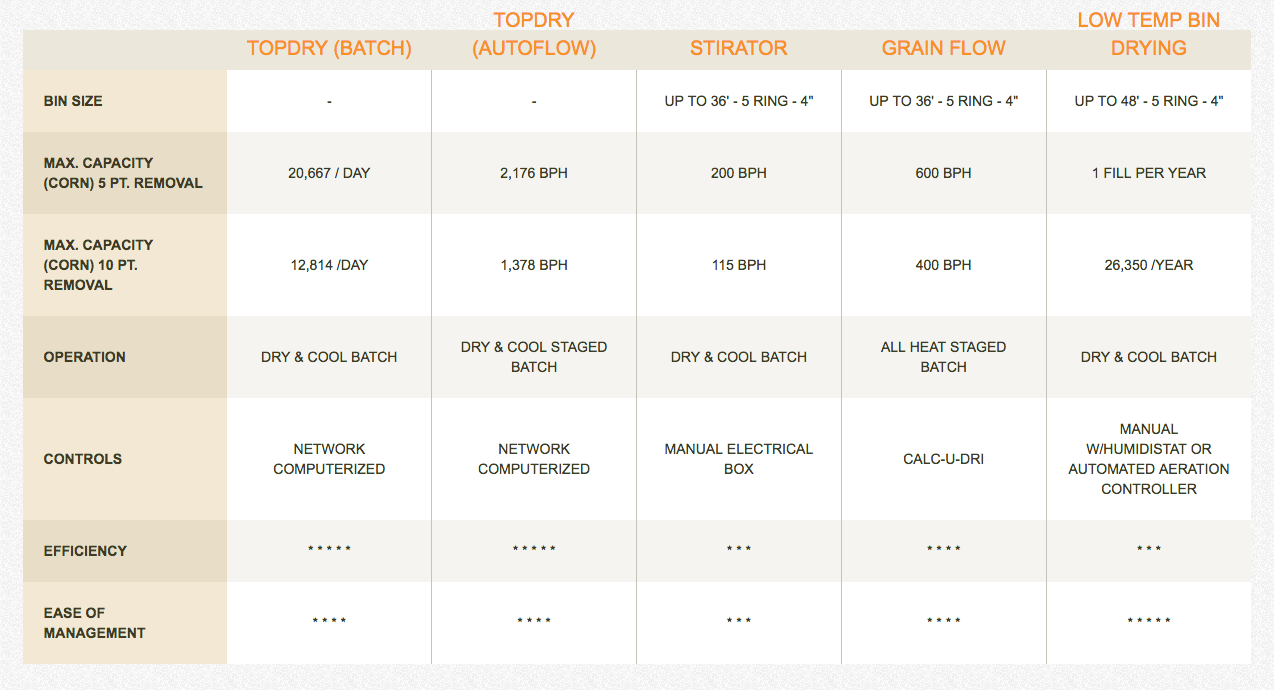

PRODUCT COMPARISON